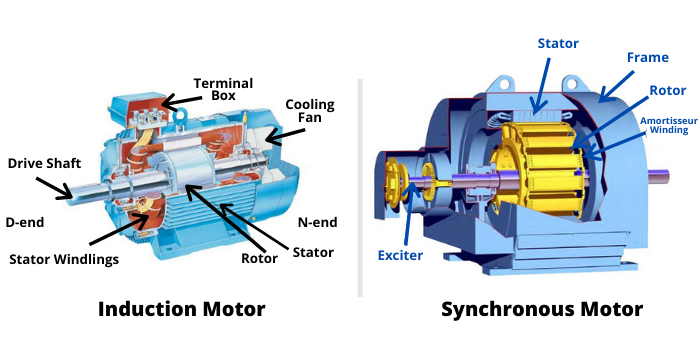

Synchronous Motor

In a Synchronous motor, the stator has axial slots, consisting of stator winding wounds for a specific number of poles. Generally, a salient pole rotor is used on which rotor winding is mounted. The rotor winding is fed with a DC supply with the help of slip rings. A rotor with permanent magnets can also be used.

Induction Motor

In an Induction motor, stator winding is also wound for a specific number of poles. But here, two different types of rotors are generally used:

- Squirrel cage rotor: the rotor bars are permanently short-circuited with end rings.

- Wound cage rotor: Windings are also short-circuited permanently. Hence no slip rings are required.

The Difference in Working Principle

Synchronous Motor Working Principle

A synchronous motor has the stator poles rotating at the synchronous speed when fed with a three-phase supply. The rotor is fed with a DC supply. The rotor needs to be rotated at speed near the synchronous speed during starting. If done so, the rotor poles get magnetically coupled with the rotating stator poles, and thus the rotor starts rotating at the synchronous speed.

Induction Motor Working Principle

In an Induction motor, when the stator is fed with a two or three-phase AC supply, a rotating magnetic field (RMF) is produced. The relative speed between the stator’s rotating magnetic field and the rotor will cause an induced current in the rotor conductors. The rotor current gives rise to the rotor flux.

According to Lenz’s law, the direction of this induced current is such that it will tend to oppose the cause of its production, i.e., the relative speed between stators RMF and the rotor. Thus, the rotor will try to catch up with the RMF and reduce the relative speed. The speed of the induction motor is always less than the synchronous speed.

Important Differences

- Synchronous motors need an additional DC power source for energizing rotor winding. Whereas induction motors never require any added source of power.

- Slip rings and brushes are required in synchronous motors. But not in induction motor (except wound type induction motor in which slip ring motors are used to add external resistance to the rotor winding).

- Synchronous motors require an additional starting mechanism to rotate the rotor near to the Synchronous speed initially. No starting mechanism is required in induction motors.

- The power factor of a synchronous motor can be adjusted to lagging, unity, or leading by varying the excitation. Whereas an induction motor always runs at a lagging power factor.

Read More